Public

Italian clay products: a material that is friendly to humans and the environment

The construction industry is devoting increasing attention to human health and the environment. Today, the performance of construction products must take into account not only supply, installation and maintenance issues but also the impact of products on the natural environment and the healthiness of the building.

Creating healthy environments with Italian heavy clay products

In recent years, the European Commission has issued a series of directives aimed at reducing the environmental impact of buildings. nZEBs (Nearly Zero Energy Buildings) are buildings with almost zero energy consumption based on construction models typical of northern Europe.

Building culture and sustainability in the Mediterranean region

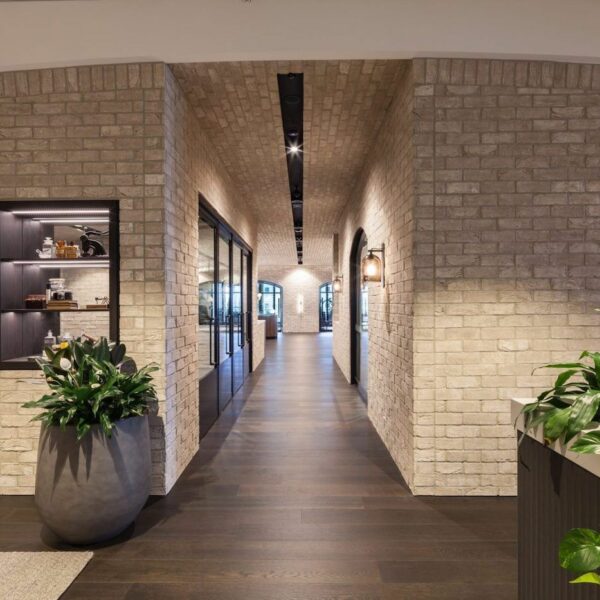

The Mediterranean region has a unique architectural heritage. To address the challenges posed by climate change and construct increasingly sustainable buildings, we need to revisit traditional methods. Solid brick masonry and well-ventilated interiors guarantee optimal comfort in all seasons while minimising environmental impact. In-depth knowledge of Mediterranean climatic conditions has made it possible to develop even more effective solutions that optimise resources and improve living standards by blending time-honoured traditions with innovative technologies.

The sustainable life cycle of Italian structural clay products

A natural material Structural clay products are sustainable materials that contain clay, a material of natural origin which is extracted using methods that are friendly to the environment and the...

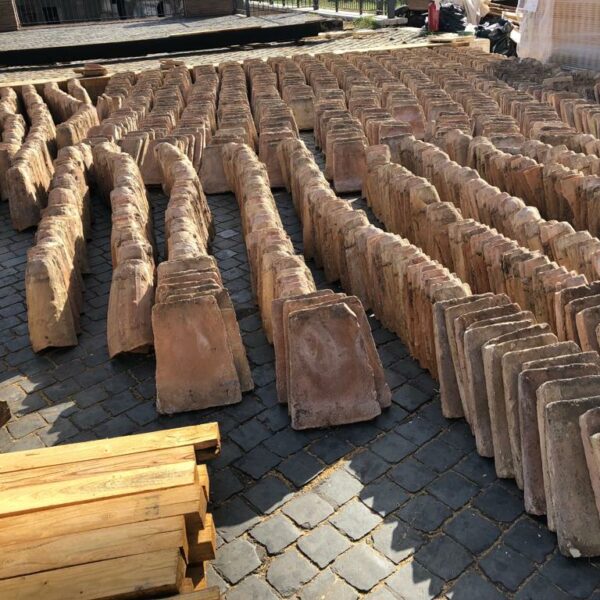

Recycling Italian clay roof tiles

In keeping with the growing awareness of environmental issues such as energy and raw materials savings and emissions reductions, in 2018 Italy appointed EPD Italy as its national Program Operator responsible for issuing environmental product declarations.

Italian clay roof tiles: for innovative and sustainable roofs

By 2050, more than 80% of the EU’s population will live in cities. Within the same timeframe, the International Energy Agency (IEA) has estimated that demand for indoor air conditioning will triple.

High energy performance buildings with Italian heavy clay products

The revised Energy Performance of Buildings Directive (EPBD) proposed by the European Commission emphasises the significant contribution of clay building products to more sustainable construction. Thanks to their characteristics, materials such as clay bricks and roof tiles reduce consumption and ensure high energy performance throughout the life cycle of buildings. They are also highly durable and can be easily recycled.

The reuse of ceramic sludge

Studies conducted by Centro Ceramica in Civita Castellana in collaboration with a number of local companies have demonstrated that sludge from sanitaryware production can be reused in the ceramic tile production process and in other sectors. Eco-friendly management of ceramic waste reduces companies’ environmental footprint and allows for cost savings.

Material effect: well-being and personality in the bathroom

Stone, marble, cement and metal are today’s most on-trend surface finishes in the field of ceramic sanitaryware. They respond to a desire for contact with the earth and with nature in general while bringing a new and highly distinctive character to any bathroom space.

Waste-proof glazing

For years, several Italian ceramic companies in Civita Castellana have been working on the innovation of their industrial processes, to produce sanitaryware and bathroom furnishings with minimum environmental impacts. Particular attention...