For several decades now, the Italian ceramic industry has embraced sustainability and corporate social responsibility as integral aspects of its identity thanks to continuous investment in new technologies, the use of selected raw materials and the optimisation of production processes.

A conference entitled “New challenges for the ecological transition in the ceramic sector”, organised in Sassuolo last February as part of the Conference on the Future of Europe, looked at the example of Coem, a medium to large sized company located in the Sassuolo ceramic district with annual revenues of more than €70 million and certifications in the fields of quality (ISO 9001), environment (ISO 14001 and EMAS) and occupational health and safety (ISO 45001).

Coem was founded in the 1970s at a time when the first agreements were being reached to reduce the ceramic district’s environmental impact. For several years now, the Italian ceramic district has become a veritable incubator of sustainable development. Italian ceramic companies are subject to regular AIA (integrated environmental authorisation) checks and controls conducted by the regional environmental protection agency ARPA to ensure that all environmental parameters are observed.

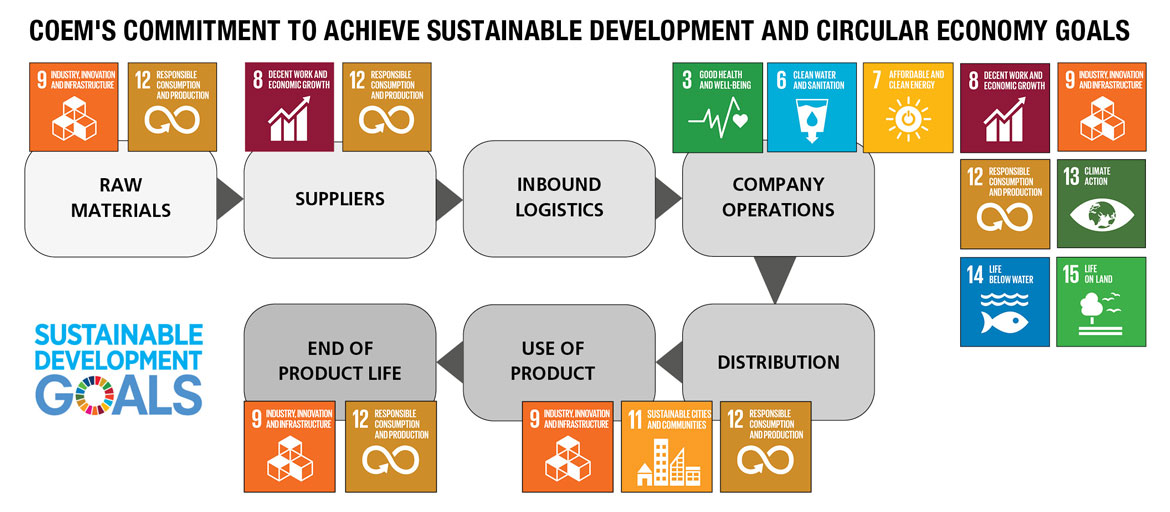

“Coem’s approach to sustainability covers the entire product lifecycle from raw material sourcing and processing through to product manufacture, use and end-of-life disposal,” says Elisa Tonelli, the company’s quality, environment and ETS manager. Suppliers are required to comply with environmental, health and safety regulations. To safeguard biodiversity, raw materials are procured from quarries that adhere to a morphological and vegetation remediation programme consistent with environmental guidelines. Raw materials are purchased preferentially within a radius of 800 km to reduce the impact of transport. Coem believes that it is important to support the local economy, which is why 99% of suppliers by value are based in Italy. In terms of logistics, its aim is to transfer raw materials using an intermodal system with a preference for the use of methods with a lower environmental impact, such as ships and trains, and using road transport only in the final stages.

The company favours the use of recycled raw materials in its ceramic mixes and as early as the 2000s had registered the Ecogres trademark for ceramic surfaces with more than 40% pre-consumer recycled content. With over twenty years of expertise in these fields, Coem has succeeded in creating products that combine a high recyclate content with excellent technical and aesthetic characteristics. Coem’s interest in sustainability issues has also led it to investigate the use of raw materials that allow for lower firing temperatures and consequently a reduction in CO2 emissions during production. For this purpose, it has designed and manufactured a product with recycled glass that allows firing temperatures to be lowered by 100°C.

The company uses closed-loop processes in which waste water from production processes can be recycled. For many years now, Italian ceramic tile producers have achieved zero liquid discharge by treating industrial wastewater and reusing it in the production process, thereby protecting surface and ground water from pollution. Coem is also able to recycle water from external production processes and to recover rainwater from some areas of its yards in the production process.

It also recycles all raw and fired waste from its production process and recovers waste from other supply chains and sector companies. In general, the ceramic industry is able to recycle almost all (99.5%) of its production and purification waste.

In terms of energy, the company prefers to purchase electricity from renewable sources. It recently installed high energy-efficiency kilns complete with an internal heat recovery system, enabling it to improve its levels of specific energy consumption. It uses a system for recovering the waste heat from all kilns in other lower-temperature thermal processes, such as spray dryers, dryers and factory heating. Thermal energy is produced using natural gas, which is the least CO2-intensive of all fossil fuels.

Atmospheric emissions are treated with purification systems in line with the best available techniques adopted in the ceramic industry. As well as reducing emissions into the surrounding area, the treatment plants also keep workplaces healthy. Lead-free products and low-odour inks are used for applications and decorations.

Primary packaging materials made of recycled and recyclable board are used, and preference is given to the use of recycled and recyclable shrink-wrap film. The company uses sorting machines with a packaging system that allows for just-in-time box assembly, resulting in savings in board consumption of up to 50% compared to a traditional packaging system.

But the sustainable approach is not limited to the factory premises. For example, as part of its “Plastic-Free Water Project” aimed at eliminating the use of plastic, Coem has equipped its premises with mains water dispensers capable of supplying purified fresh still and sparkling water at a minimal cost. This initiative is appreciated by employees and benefits the environment by avoiding the use of around 40,000 plastic water bottles per year.

Many aspects of sustainability are also intrinsic characteristics of ceramic materials themselves. These include their long lifespan (50-75 years on average) and their inertia, which means that end-of-life ceramic material can be recycled by authorised recycling companies and used for example for backfilling pipeline trenches, as ballast in roadbed construction and for soil consolidation.

Thanks to its sense of environmental responsibility, a characteristic shared by many companies in the Sassuolo ceramic district, Coem is able to achieve many of the goals in the UN’s 2030 Agenda for Sustainable Development. These include: (3) Good health and well-being; (6) Clean water and sanitation; (7) Affordable and clean energy; (8) Decent work and economic growth; (9) Industry, innovation and infrastructure; (11) Sustainable cities and communities; (12) Responsible consumption and production; (13) Climate action; (14) Life below water; (15) Life on land; (16) Peace, justice and strong institutions.

May 2022

Dealers

Dealers

Architects

Architects