Technical

Floor coverings and slip resistance | by Barbara Mazzanti and Leonardo Sanseverino (Centro Ceramico)

Slip resistance is one of the most important characteristics to be taken into consideration in the design, production and maintenance of pedestrian floors. It is an important parameter not just for designers and manufacturers of floor covering materials but also for users, whether the flooring is installed in residential, public or private spaces or in areas used for industrial activities.

The choice of floor covering material must take account of the place of use, the risks associated with the specific conditions of use and the legal and regulatory requirements in force in the country of installation. It is also important to take account of the many factors that influence the relative motion between two contact surfaces (e.g. floor and sole of footwear/bare feet, area, shape/profile, composition of the contact materials, walking speed, weather conditions, presence of contaminants, etc.).

In Italy, Ministerial Decree D.M. 236/89 states that, in private buildings and subsidised and social housing, floors “… in common and public use areas must be “non-slip”, i.e. made from materials whose dynamic coefficient of friction, measured using the Tortus floor friction tester in accordance with the method of the British Ceramic Research Association Ltd. (B.C.R.A.) Rep. CEC. 6/81, is higher than the following values:

– 0.40 using leather as the sliding element over a dry floor;

– 0.40 using standard hard rubber as the sliding element over a wet floor.”

In Germany, the German Social Accident Insurance (DGUV) establishes the permitted levels of slip resistance for different areas of use: wet barefoot areas (e.g. saunas, swimming pools, etc.) are covered by DGUV 207-006, and workplaces and working areas by DGUV Regel 108-003. The test method uses a ramp to determine the angle of inclination at which the operator is no longer able to walk without falling. The operating conditions are as follows:

In Germany, the German Social Accident Insurance (DGUV) establishes the permitted levels of slip resistance for different areas of use: wet barefoot areas (e.g. saunas, swimming pools, etc.) are covered by DGUV 207-006, and workplaces and working areas by DGUV Regel 108-003. The test method uses a ramp to determine the angle of inclination at which the operator is no longer able to walk without falling. The operating conditions are as follows:

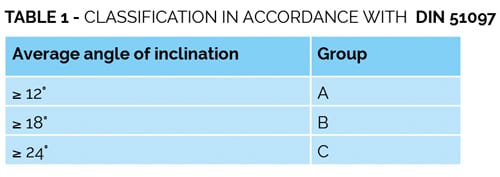

– on floor covering materials in areas normally used barefoot (e.g. saunas, swimming pools, etc.): operator walks barefoot on a test surface contaminated with water + neutral wetting agent. The reference standard is DIN 51097, which defines 3 slip resistance classes: A, B, C (Table 1).

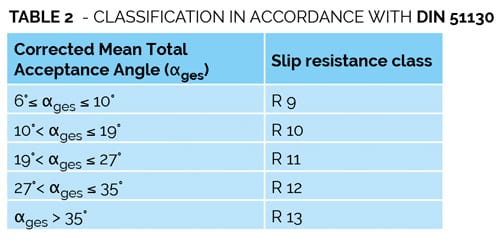

– for floor covering materials in workplaces and industrial transit areas: operator wearing safety footwear walks on a test surface coated with oil. The reference standard is DIN 51130, which defines 5 classes from R9 to R13 (Table 2).

In France, standard NF P05-011 “Revêtements de sol – Classement des locaux en fonction de leur résistance à la glissance”, approved in 2019, establishes a similar type of classification of areas of use to the German standard. Floor covering materials are evaluated using the ramp method for walking barefoot and with footwear (CEN/TS 16165 ANNEX A, ANNEX B) and are classified into 4 and 5 classes respectively (PN6, PN12, PN18, PN24; PC6, PC10, PC20, PC27, PC35).

In France, standard NF P05-011 “Revêtements de sol – Classement des locaux en fonction de leur résistance à la glissance”, approved in 2019, establishes a similar type of classification of areas of use to the German standard. Floor covering materials are evaluated using the ramp method for walking barefoot and with footwear (CEN/TS 16165 ANNEX A, ANNEX B) and are classified into 4 and 5 classes respectively (PN6, PN12, PN18, PN24; PC6, PC10, PC20, PC27, PC35).

The reference standard in Spain is the Documento Básico SUA of 2019, a building safety document that sets out requirements for floor covering materials in relation to various risks, including falls. The materials are classified on the basis of slip resistance measurements performed using the test method indicated in UNE ENV 12633 (withdrawn, but still taken as reference and mentioned in the Documento Básico), which specifies the use of the pendulum method; floor covering materials are classified into 4 classes (0-3) according to their intended use and level of risk.

When used as a floor covering material, the slip resistance of ceramic tiles must be declared for the purposes of CE marking in accordance with Annex ZA (Table ZA.1.1) of standard EN 14411 Ceramic tiles – Definition, classification, characteristics, assessment and verification of constancy of performance and marking. For the purposes of CE marking, the value must be declared using one of the test methods listed in Technical Specification CEN/TS 16165 (ramp, pendulum and generic tribometer) unless a different method is required by law in the European country where the material is sold. Technical committee CEN/TC 339 Slip resistance of pedestrian surfaces – Methods of evaluation has recently begun work on developing a shared European standard based on CEN/TS 16165.

In addition to the test methods set out in the standard, it is worth mentioning that it is possible to study the surface and its texture using an optical profilometry technique, which involves measuring parameters such as maximum height of the profile (Rz), mean spacing of profile elements (Rsm), root mean square slope (Rdq) and core roughness depth (Pk). This technique represents an innovative approach that is extremely useful for developing products with high slip resistance right from the design stage. Ceramic tiles come in a wide range of sizes and thicknesses that make them suitable for outdoor use, and their various surface finishes mean they can be used in a variety of applications such as pool surrounds and garden walkways, thereby maintaining stylistic continuity between indoor and outdoor spaces. This wide range of applications derives from the ability of ceramic tiles to cover all slip resistance classes (e.g. from R9 to R13 according to DIN 51130), unlike competitor materials which are limited to indoor use and/or applications requiring only low levels of slip resistance.