Saving resources is a key objective for protecting the natural heritage. The Italian ceramic tile industry has adopted targeted strategies to reduce its future environmental impact and has invested in balancing efficiency and eco-sustainability and in minimising the consumption of raw materials.

A circular production process

Italian ceramic tile is an inert product made from natural materials. Instead of being sent to landfill, waste ceramic body and finished product rejects are 100% reused in the production process, thereby reducing the consumption of natural resources.

The high recyclability of Italian ceramic materials brings the following advantages in terms of consumption and atmospheric emissions:

- Less use of virgin raw materials.

- Reduction in waste and polluting discharges.

- Minimal use of natural gas for firing products.

- Lower CO2 emissions.

To reuse is to save

The Italian ceramic tile industry’s environmental impact has decreased considerably in recent years. By reusing solid waste, today’s ceramic factories recover 9.3%(1) of their raw material requirements. Unfired waste is fed directly back into the production cycle, while fired waste is crushed to reduce its size and then reintroduced into the body preparation process.

More than 100% of unfired and fired waste is reused

The Italian ceramic tile industry’s production process has always been geared towards environmental sustainability. Over the years, the industry has combined high levels of quality with major innovations aimed at achieving the maximum reduction of waste.

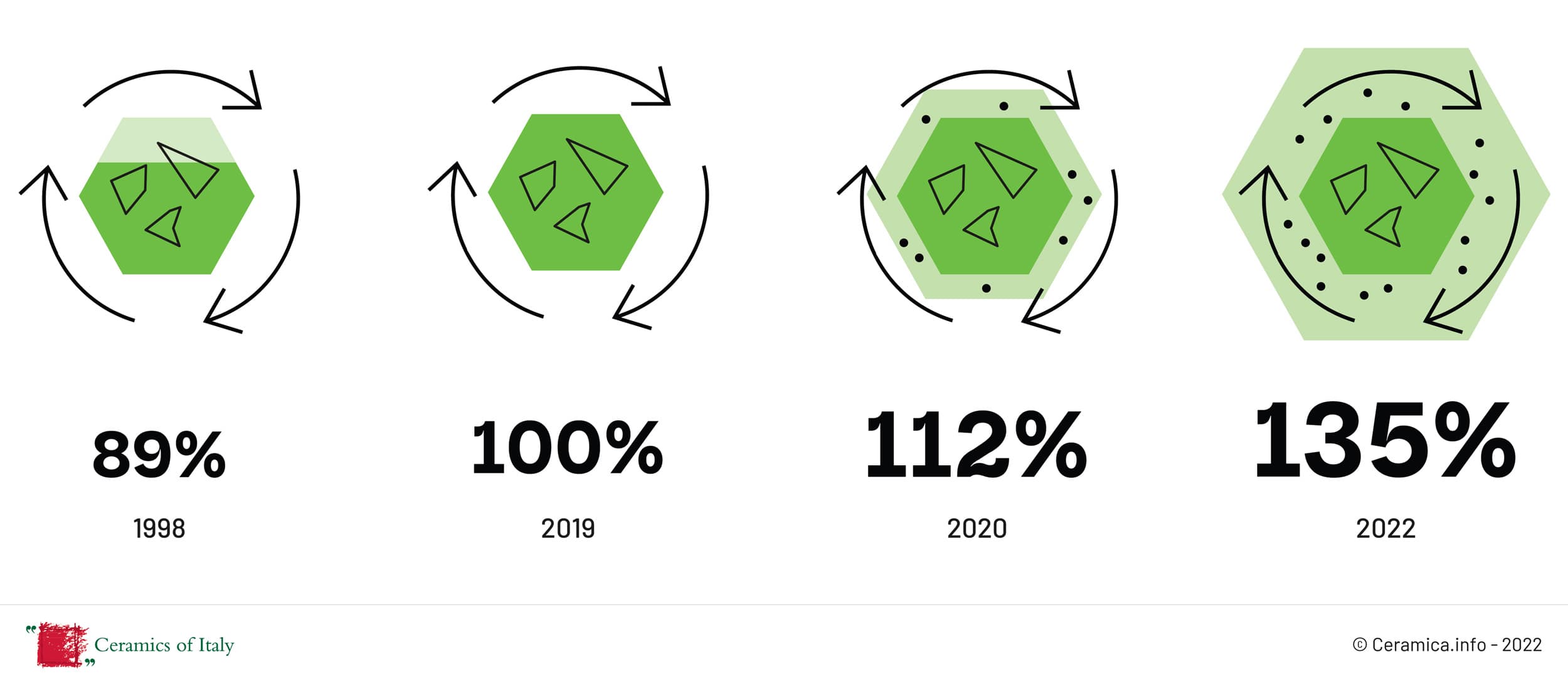

From 1998 to 2019, the Italian ceramic tile industry saved more than 600,000 tonnes of raw materials such as clays and feldspars each year. Over the same period, the percentage of unfired and fired production waste that was reused increased from 89% to 100%.

For the first time in 2020, the Italian ceramic tile industry achieved such a high level of technological innovation that it is able to recycle all its own waste as well as waste originating from other industries.

Ratio between waste returned to the production cycle and waste generated

Every drop counts

The Italian ceramic industry does not waste a single drop of water. Ceramic tile production plants purify and reuse 99% of wastewater in the production process. This means there is practically zero risk of groundwater pollution caused by water discharges.

The Italian ceramic tile industry saves water to avoid harming the environment

Towards the highest levels of excellence

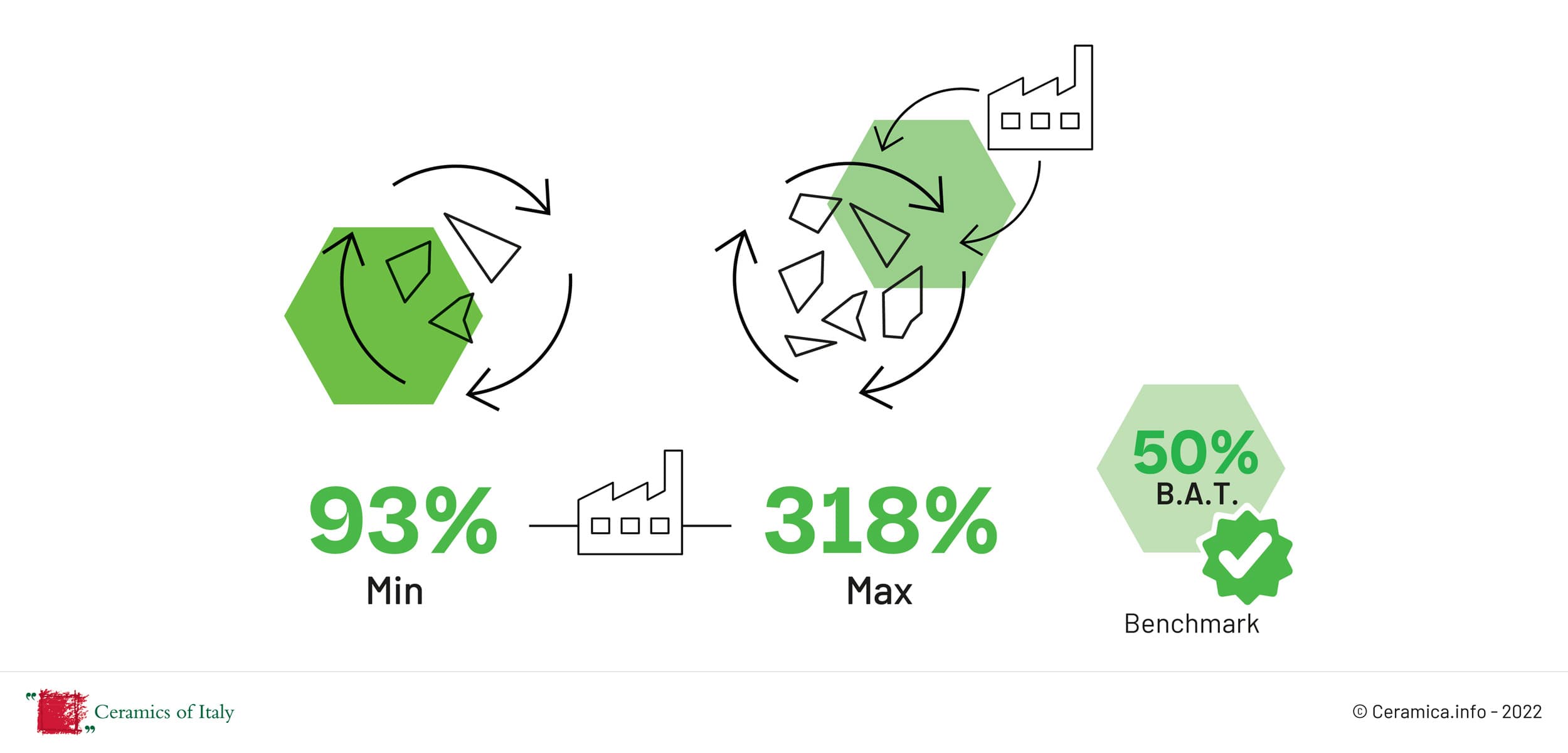

The Italian ceramic tile industry far exceeds the minimum thresholds of the Best Available Techniques (BATs) for waste treatment issued by the EU Commission in 2018. Values for the Waste Recycling Factor vary from a minimum of 93% to a maximum of 318%, well above the 50% threshold required by industry BATs.

Architects

Architects

Dealers

Dealers